Features

A Brief Description

My customers tend to be players who have reached a point in their drumming career where quality and individuality are very important.

I am not a mass producer of drums. All of my drums are built by hand, one at a time. The three core areas of focus for me when building a drum are: Sound, Aesthetic, and Functionality.

All of the features of my drums revolve around this core. If I were to just buy commodity shells and hardware, I wouldn't be able to achieve what I believe a drum could/ should be. For this reason, I design and make my own shells and lugs.

Shells

All shells are painstakingly constructed using the segment method. Wood is hand picked for it's appearance, size, and structural integrity. The wood is accurately cut into segments. The segments are then glued into a ring. The rings are then stacked on top of each other and glued to achieve the desired shell depth.

After the shell is allowed to cure, the outside of the shell is machined perfectly round to a thickness of 8mm and then sanded to prep for finishing.

Why are Rathkamp Drums shells different?

- I am able to select any type of wood which gives my a huge sonic and visual palette.

- I control the quality. I'm not at the mercy of a supplier. If I'm not happy with a shell, it goes into the fireplace.

- Rathkamp Drums shells are round.

- Rathkamp Drums shells are dead flat. I've invested in processes and Quality Control equipment that ensures that every single bearing edge is perfectly flat, increasing a nice sweet sustain, and making my drums a dream to tune.

- At no point in time is the wood ever stressed. This means that the wood remains in a relaxed state throughout the drum's life and that there are no internal stresses that could cause variation in sound or that could crack the shell.

- Because of the staggered gluing of the shell, the structural integrity is incredibly sound. I have literally bounced my shells on a cement floor, only to have them come back into my hands like a basketball. Try doing that with a stave shell.

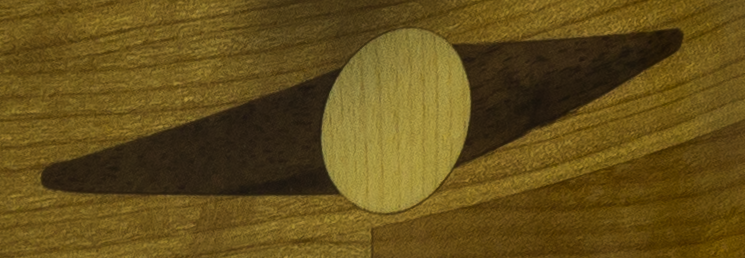

Inlays

There are a few drum builders who offer inlays from banding similar to this, but all of these are mass-produced. I thought I could come up something that was maybe a little more personal, a chance to further develop my aesthetic. All of these designs are simple but original. Here are some examples:

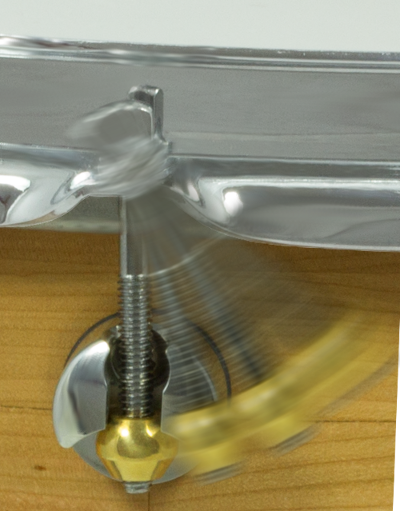

Lugs/ Hardware

Rathkamp Drums uses the V4DE quick-release lugs. These lugs offer great functionality and a very clean, minimalist look. Every lug is hand-polished by me (not my favorite job, but the results are fantastic). All hardware is mounted to the drum with high-quality stainless steel fasteners.